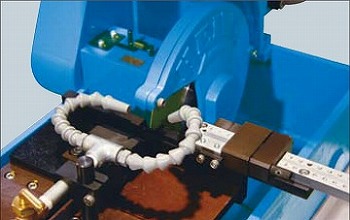

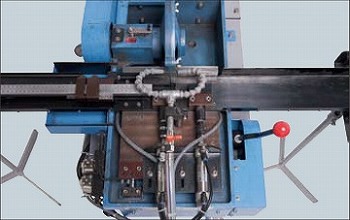

A cutting machine with a rack-type lever that uses the table travel cutting method and which provides easy precision cutting of bars of a diameter of up to φ30mm. The dedicated air vise (option) provides superior productivity and operability in the mass-production of consistent size materials.

Characteristics

- High power with 1.5kW spindle motor; cuts up to 30mm bars precisely and at high speed.

- Equipped with a cut meter that displays the cutting load The cut meter aids in adjusting the cutting amount.

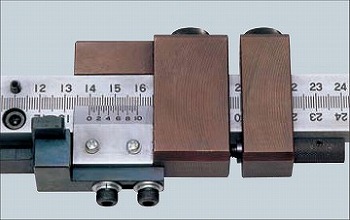

- Equipped with vernier scale. Allows the position of the material to be fine-adjusted easily.

-

General-purpose type vise

Double clamp system that reduces burrs and which is provided with a 3mm-depth cutting wheel passage. Effective cutting length: 3-150mm. Equipped with a 150mm vernier scale on the right-hand side.

-

Special-purpose type vise for pins

Designed exclusively for the extruding pins of die. Cut measurements available from 50mm to 300mm and equipped with a 300mm vernier scale on the left-hand side.

-

Vernier scale

* General-purpose type includes 150mm scale as standard equipment (optional specifications: 300mm and 500mm)

* Special-purpose type for pins includes 300mm scale as standard equipment (optional specification: 500mm)

- A low voltage protection switch with a thermal feature is adopted

- Special Accessory Air Vice(Single Clamp)

- Special Accessory Air Vice(Double Clamp)

Working with the cutting operation of a lever the vise automatically clamps and unclamps pieces of work using air pressure. Very effective in mass-production cutting as it eliminates the necessity of holding pieces of work with your hands.

Standard Specifications

| N-7 | |

|---|---|

| Standard cutting capacity | ○□pipe 30mm, ●■solid bar 30mm |

| Jaw opening size | 0-30mm |

| Table travel | Manual rack and pinion |

| Spindle revolutions per minute | 3000rpm・50Hz/60Hz |

| Diameter of cutting wheel | φ205mm/φ25.4mm |

| Spindle motor | AV200V・3 phase・2P・1.5kW |

| Coolant pump, Tank | AV200V・3 phase・40W, 30liters |

| Dimensions (W x L x H) | 850mm x 780mm x 1170mm |

| Machine weight | 98kg |

| Accessories |

1 set of vernier scales, material support side tables,

1 set of cutting wheels for testing, FINECOOL, and 1 set of Paper Filters |

* Please consult the voltage change.

FiNECUT N-7 Sample Application

Place fine materials such as injection needles or materials to be cut in a thermal shrinking tube, heat the tube to shrink and thus bundle the materials, and then cut them in one go.

* Please use an industrial dryer or boiling water for the heating process.

* Please contact us for more detailed product information on the tubes.

| Total Number | Number of internal Total Number materials inside (n) |

Number of external materials (a) |

|---|---|---|

| 7 | 3 | 2 |

| 19 | 5 | 3 |

| 37 | 7 | 4 |

| 61 | 9 | 5 |

| 91 | 11 | 6 |

| Parts name (nominal folding width: mm) |

Applicable bundle diameter (mm) |

Code No. |

|---|---|---|

| 29.0 | 17.0 | HC-15 |

| 41.0 | 24.0 | HC-20 |

| 50.0 | 29.0 | HC-25 |

| 59.5 | 34.0 | HC-30 |

| 66.5 | 38.0 | HC-35 |

NASTON GOLD

NASTON GOLD NASTON

NASTON FINE CUT

FINE CUT Supplies for FINE CUT

Supplies for FINE CUT General catalogue

General catalogue