HS-45A C Type

Upgraded operability has resulted in less space being required and greater accuracy in corresponding to the various work environments.

Characteristics

- Improved operability with steering wheel on the left side of machine.

- Antirust vise and work table.

- Independent operating board and power BOX for greater operability.

- More space efficient because of a machine body width of just 720mm.

- Equipped with a water gun for cleaning.

Vise Line Up

| ①Long Vise | SP-V11 |

|---|---|

| ②Surface Rotary Vise | SP-V12 |

| ③Long-type Surface Rotary Vise | SP-V13 |

| ④Double Vise | SP-V14 |

| ⑤Long-type Double Vise | SP-V15 |

* See the available options on pages 12-13 for the lineup of optional accessories and specifications.

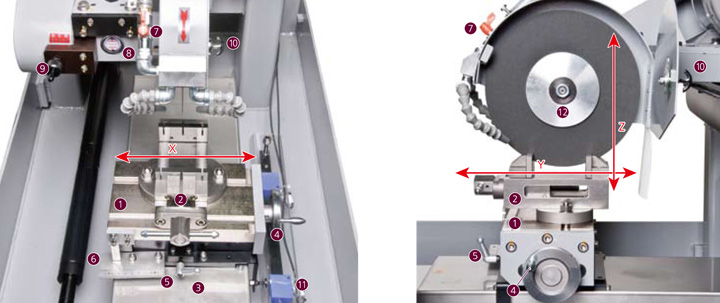

- ① Work table [electro-less nickel plating]

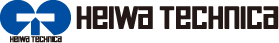

- ② Standard stainless steel vise [jaw opening size 0 - 80mm]

- ③ Stainless steel front-rear feed cover [contaminant-proof]

- ④ Work table cross-feed steering wheel

- ⑤ Work table stopper knob

- ⑥ Direct-read stainless steel scale

- ⑦ Coolant discharge adjustment cock

- ⑧ Oil pot window

- ⑨ Spindle stopper for changing cutting wheel

- ⑩ Cutting wheel cover open/close knob

- ⑪ Position sensor for cutting direction travel

- ⑫ Cutting wheel flange [aluminum]

- X Work table travel: 60 cross feed (manual)

- Y Cutting direction travel: 210mm front to rear movement (when operated with steering wheel on right side)

- Z Spindle travel: 200mm vertical movement (when operated with steering wheel on left side)

Standard Specification

| HS-45AC | |

|---|---|

| Standard cutting capacity | ○□pipe 40mm, ●■solid bar 30mm, ■plate 15mm x 75mm |

| Flake cutting | 0.2mm at φ20mm (hard metals) |

| Cutting tolerance | Squareness 0.05mm, parallelism 0.1mm for SK steel φ20mm |

| Work table travel (X, Y) | 210mm in cutting direction (manual)・60mm in cross feed (manual) |

| Spindle travel (Z) | 190mm vertically (front steering wheel operation) |

|

Automatic cutting,

Return speeds |

6-100mm per min. (stepless), 100mm per min. (fixed) |

| Diameter of cutting wheel | φ230mm・φ205mm/φ25.4mm |

| Diameter of flange | φ110mm (φ90mm: optional accessory) |

|

Diameter of spindle,

Revolutions per minute |

φ25.4mm, 3000rpm |

| Spindle motor | AC200V・3 phase・2P・1.5kW |

| Coolant pump, Tank | AC200V・3 phase・40W, 30 liters |

| Automatic cutting motor | AC200V・single phase・10W |

| Dimensions (W x L x H) | 720mm x 1035mm x 1450mm |

| Machine weight | 290kg |

| Accessories |

Stainless steel standard vise, cleaning water gun, 1 set of cutting

wheels for testing, FINECOOL, spindle oil, and 1 set of Paper Filters |

* Please consult the voltage change.

NASTON GOLD

NASTON GOLD NASTON

NASTON FINE CUT

FINE CUT Supplies for FINE CUT

Supplies for FINE CUT General catalogue

General catalogue