List of Optional Vises and Products for FiNECUT Series

○ Applicable - Not applicable

| Product Name | Code No. | HS-100G | HS-45AC | HS-25/25A | ACE20/30Z | SP-7/310Z |

|---|---|---|---|---|---|---|

| ①Long Vise | SP- V11 | ○ | ○ | - | - | - |

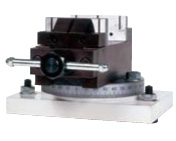

| ②Surface Rotary Vise | SP- V12 | ○ | ○ | Dedicated type for 25 | - | Dedicated type for SP |

| ③Long-type Surface Rotary Vise | SP- V13 | ○ | ○ | - | - | - |

| ④Double Vise | SP- V14 | ○ | ○ | - | - | Dedicated type for SP |

| ⑤Long-type Double Vise | SP- V15 | ○ | ○ | - | - | - |

| ⑥Double Vise with Scale | SP- V18 | ○ (requires consultation) |

○ (requires consultation) |

- | - | Dedicated type for SP |

| ⑦Air Vise | SP- V17 | ○ | ○ | - | - | Dedicated type for SP |

| ⑧Gonio Stage | SP- V16 | ○ | - | Dedicated type for 25 | - | - |

| ⑨Dedicated Jigs | ○ | ○ | ○ | ○ | ○ | |

| ⑩Special Flange | SP- W17 | ○ | ○ | ○ | ○ | ○ |

List of Optional Specifications for FiNECUT Series

■ Recommended option ■ Standard equipment ○ Applicable - Not applicable

| Type | Product Name | Code No. | HS-100G | HS-45AC | HS-25/25A | ACE20/30Z | SP-7/310Z |

|---|---|---|---|---|---|---|---|

| Coolant | ① Simple Filter Separator | ST-TF | ○ | ○ | — | ○ | ○ |

| ② Magnet Separator | ST-TM | ○ | ○ | — | ○ | ○ | |

| ③ Centrifugal Separator | ST-TC | ○ | ○ | — | ○ | ○ | |

| ④ Settling Tank Separator | ○ | — | — | ○ | ○ | ||

| ⑤ Pressure Filter Separator | ○ | ○ | — | ○ | ○ | ||

| ⑥ Standard Stainless Filters | ○ | ○ | — | ○ | ○ | ||

| Safety Measures | ⑦ Earth Leakage Circuit Breaker | OP-ELB | Standard Equipment | Standard Equipment | ○ | Standard Equipment | Standard Equipment |

| ⑧ Emergency Stop Button | ○ | ○ | ○ | ○ | ○ | ||

| ⑨ Front Cover Interlock | OP-IL | Standard Equipment | ○ | Standard Equipment | — | Standard Equipment | |

| ⑩ Right/Left Cover Interlock | ○ | ○ | — | — | — | ||

| ⑪ Interlock with Magnetic Lock | ○ | ○ | — | — | ○ | ||

| ⑫ Indication Lights | ○ | ○ | ○ | ○ | ○ | ||

| Environment Measures etc. |

⑬ Cleaning Water Gun

(coolant circulation) |

OP-WA | Standard Equipment | Standard Equipment | — | Standard Equipment | Standard Equipment |

|

⑭ Internal Light

(ceiling moisture-proof LED) |

OP-LF | ○ | ○ | — | — | Standard Equipment/ ○ | |

| ⑮ Moisture-proof LED Spot Light | OP-LS | ○ | ○ | — | — | ○ | |

| ⑯ Multi-blade | OP-HM | ○ | — | — | — | — | |

| ⑰ Enhanced Spindle Motor | OP-HI | — | — | — | —/○ | ○/— | |

| ⑱ Embedded Spindle Rotation Inverter | OP-RCO | ○ | ○ | ○ | ○ /Standard Equipment | —/Standard Equipment | |

| ⑲ Mist Collector | OP-MC | ○ | ○ | — | — | ○ | |

| ⑳ Stainless Steel Upper Body Cover | ○ | ○ | — | — | ○ | ||

| ㉑ Antirust Treated Internal Body | OP-AC |

○

(requires consultation) |

○

(requires consultation) |

○

(requires consultation) |

○

(requires consultation) |

○

(requires consultation) |

|

| ㉒ Colored Body | OP-CO | ○ | ○ | ○ | ○ | ○ | |

| ㉓ Line Marker | ○ | ○ | — | — | — |

Application Example of FiNECUT Series Cutting

Bundle Cutting

Place fine materials such as injection needles or materials to be cut in a thermal shrinking tube, heat the tube to shrink and thus bundle the materials, and then cut them in one go.

* Please use an industrial dryer or boiling water for the heating process.

* Please contact us for more detailed product information on the tubes.

|

Parts Name Wax Set

(nominal folding width: mm) |

Applicable bundle diameter

(mm) |

Code No. |

|---|---|---|

| 29.0 | 17.0 | HC-15 |

| 41.0 | 24.0 | HC-20 |

| 50.0 | 29.0 | HC-25 |

| 59.5 | 34.0 | HC-30 |

| 66.5 | 38.0 | HC-35 |

Wax Cutting

- * Please use an industrial dryer or

hotplate for the heating process.

Using thermo-softened wax materials that are difficult to clamp or are breakable are powerfully adhered to jigs for cutting. The material can be removed from the jig after the cutting by heating the wax.

Wax Set

- ① A wax (general purpose): softens at 68 degrees C/adhesive force 44kg/cm2

- ② B wax (small adhesive area): softens at 75 degrees C/adhesive force 162kg/cm2

- ③ Cleaning liquid I/II

- ④ Cleaning tray

- ⑤ Wax melting container

- ⑥ Abrasive stick WA/GC (for dresser)

- ⑦ Glass mount plate for cutting samples

- ⑧ Bake mount plate for fixing vice (10 of the above 8 types of items are included in a set.)

NASTON GOLD

NASTON GOLD NASTON

NASTON FINE CUT

FINE CUT Supplies for FINE CUT

Supplies for FINE CUT General catalogue

General catalogue